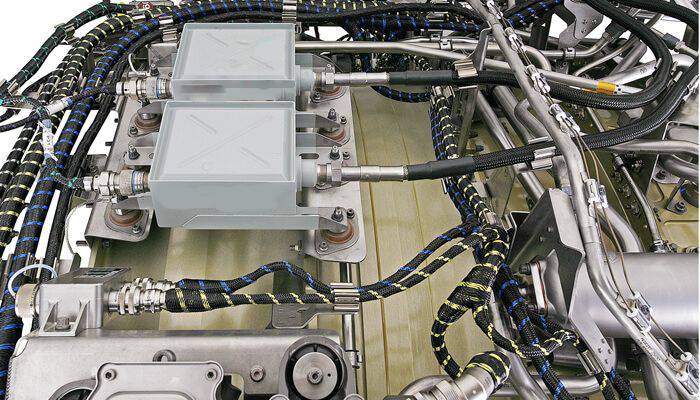

System Integration

VARSITY goes beyond cable harness manufacturing in integrating it with sub-systems such as relay boxes, power supply, switching units etc. often a high value-add service to customers.

Capabilities

-

Indigenous sourcing of boxes/mechanical parts

VARSITY, with it’s in-house expertise and partners who are specialists in machining and surface treatment, provides Integration services that meet high demands of the Customers.

-

Indigenous sources for Finishing (coating and painting)

Surface treatment for machined components viz. chromate conversion, passivation, hard chrome, electroless plating can be offered by us. Inspection for coated thickness is carried out as part of acceptance.

-

Good local Raw material sources for mechanical panels

Mild steel, stainless steel in grades 304 and 316, aluminium alloy HE-15, HE-30 All in sheet or standard extruded sections. Alloy castings in various types of steels and aluminium and copper can be offered by us. These are taken up for machining after checking chemical composition and physical property tests.

-

Component sourcing from Indian/Global suppliers

Relays, electrical accessories viz switches, lamps, push buttons, etc meeting MIL standard, variety of connectors and related accessories meeting Military standards.

-

Assembly, integration and electrical testing

Control boxes, elecro-mechanical sub systems, Control panels meeting various military standards e.g. MIL-STD-810, JSS-55555, MIL-Std-461 and equivalents in DEF standards.

-

Certified to do Electronic Assemblies vide IPC A 610.

-

Support during functional testing at customer end .

Includes fitment, wiring, testing and assistance for third party inspection of subsystems to create a totally integrated sub-system / System

-

ATP as per customer requirements.

Functional tests, electrical tests for reliability, Environmental (ESS) tests for qualification / acceptance. as per MIL-Std-810 / JSS-55555 and equivalent DEF standards for ground, marine and airborne systems.